In the previous article, we mentioned how to judge the finish of door hardware through the surface. This time we will talk about what testing need to be done for the surface treatment. The finishes of door hardware not only affects the beauty and the feeling of the door hardware, but also relates to the oxidation resistance of the door hardware, especially in coastal areas or areas with humid climates. If the finish of door hardware is not done well, it will be easy to oxidize and cause white spots on the surface.

We will still take the door handle as an example in this time. The finish of the door handle is mainly determined by which kind of surface treatment the door handle is made. However, there are some testing that are required for all surface treatments.

1. Salt Spray Test. The most common method of salt spray test is to put the product in the salt spray test equipment, and evaluate the corrosion resistance of the product by artificially creating a simulated salt spray environment. The result of the test is usually an important indicator of the surface durability of the product. The testing standard are usually divided into 48h, 72h, 96h, etc. The longer the time, the better the corrosion resistance of the product surface.

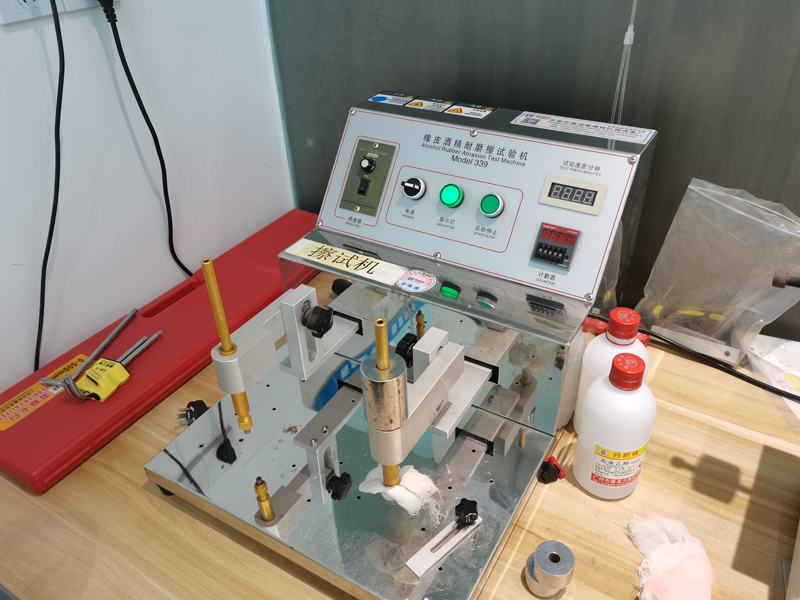

2. Alcohol abrasion test. Wrapping a 500g weight with gauze, dip it in a 95% medical alcohol solution, and wipe it back and forth 50 times at a speed of 2 back and forth / sec within a 60mm length of the product. If the product surface has not faded as qualified, the test is mainly to detect the alcohol resistance of the product surface.

If the door hardware passes the above two tests, it basically means that the surface of this product has a long service life, and it is not easy to have white spots and rust. One more thing to mention here, if the finish of the door hardware is spray paint, one more test is needed: cross-cut test.

Cross-cut test is to use cross-cut tester to draw 10*10 1mm*1mm small grids on the surface of the product, and then use 3M 600 tape to stick the tested small grid, quickly pull off the tape, and perform two tests at the same position. The paint peeling ratio can be divided into 5B, 4B, 3B, 2B, 1B and 0B. The larger the number, the stronger the paint adhesion, and the less likely the product will peel off.

Today’s sharing ends here, if you want to know more about door hardware, welcome to visit our website.

Post time: Jul-09-2021